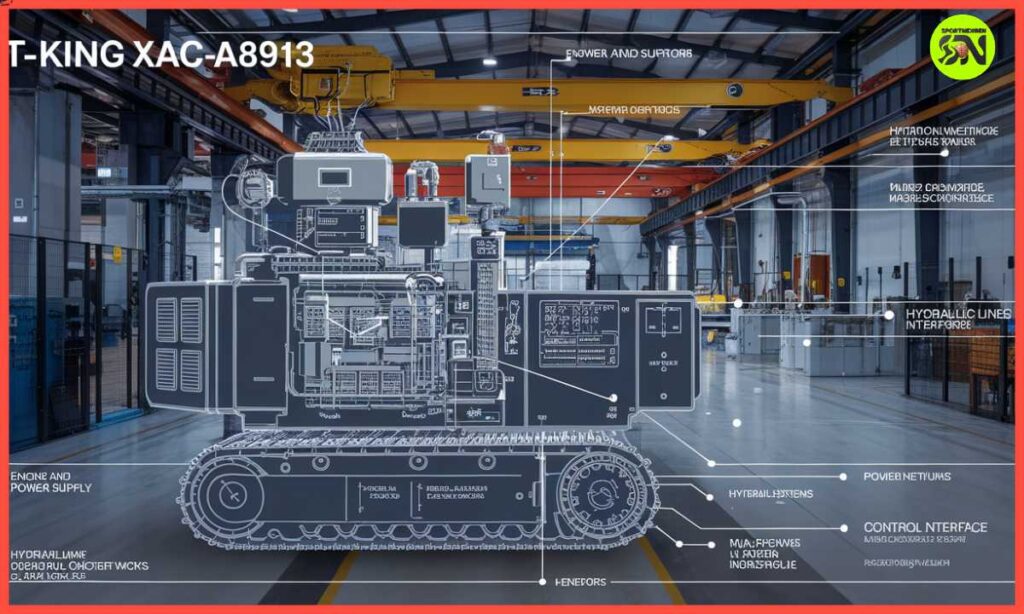

The T-King XAC-A8913 represents a cornerstone component in modern industrial and manufacturing environments, where precision engineering meets operational excellence. A thorough understanding of its diagram is crucial for professionals seeking to optimize performance.

Conduct effective troubleshooting, and maintain operational efficiency. This comprehensive guide explores the detailed aspects of the T-King XAC-A8913 diagram, providing valuable insights into its components, functions, and real-world applications.

Introduction to T-King XAC-A8913

The T-King XAC-A8913 stands as a testament to modern engineering excellence, finding applications across diverse industrial sectors including manufacturing, construction, and automated systems. Its reputation stems from its robust construction and versatile operational capabilities.

The key to mastering this sophisticated machinery lies in understanding its intricate diagram, which provides detailed mapping of all essential systems from power distribution to sensor networks.

Critical Components of the T-King XAC-A8913

The T-King XAC-A8913 diagram showcases four primary systems that work in harmony: the engine and power supply, hydraulic systems, electrical networks, and control interfaces. Each component is meticulously detailed, allowing technicians to understand their interconnections and dependencies for optimal operation.

Engine and Power Supply

The diagram meticulously details the engine configuration and power distribution network, illustrating the complex web of electrical circuits and energy pathways. This section is fundamental for understanding the machine’s power generation and distribution systems, ensuring optimal performance across all components.

Hydraulic and Pneumatic Systems

Within the T-King XAC-A8913, the hydraulic systems play a vital role in transforming hydraulic pressure into mechanical force, enabling both heavy-duty operations and precise movements. The diagram offers comprehensive insights into the pump systems, hydraulic motors, cylinders, and actuators that form the backbone of these operations.

Electrical System

The electrical system mapping provides a detailed overview of component interconnections, including sophisticated wiring harnesses, control modules, and various input/output devices. This intricate network ensures seamless communication and operation throughout the machine.

Control Panel and User Interface

The control interface serves as the primary point of interaction between the operator and the machine. The diagram extensively documents the arrangement of controls, including digital displays, control switches, and monitoring systems, providing essential information for operational management.

Reading the T-King XAC-A8913 Diagram

Understanding the T-King XAC-A8913 diagram requires familiarity with technical symbols and component layouts. The diagram utilizes standard industrial notation, making it accessible for trained professionals while providing detailed insights into system operations and relationships.

Effective interpretation of the T-King XAC-A8913 diagram requires a systematic approach:

- Begin with Fundamentals: Master the basic symbols and notations used throughout the diagram, recognizing standard representations for power sources, motors, and connections.

- Comprehend Layout Structure: Study the arrangement and interconnection of components to understand operational flow and critical system pathways.

- Review Component Specifications: Focus on technical details such as voltage specifications, connector types, and component identifiers crucial for maintenance and troubleshooting.

Read This Blog:https://sportnexgen.info/tekkit-npc-dying-chat/

T-King XAC-A8913 Practical Applications and Troubleshooting

The T-King XAC-A8913 diagram serves as an essential reference for maintenance, repairs, and system upgrades. Its detailed mapping helps technicians quickly identify issues, plan improvements, and conduct training sessions for new personnel.

Maintenance and Repairs

The diagram serves as an essential reference for both routine maintenance and emergency repairs, enabling technicians to quickly identify components and understand their relationships within the system.

System Enhancements

For professionals looking to upgrade the T-King XAC-A8913, the diagram provides crucial insights into potential enhancement opportunities and integration possibilities with newer technologies.

Training and Education

As an educational tool, the diagram offers invaluable support for training new technical staff, providing a comprehensive visual guide to the machine’s internal systems and operations.

Applications of the T-King XAC-A8913 Diagram

The T-King XAC-A8913’s versatility makes it invaluable across multiple industries, from manufacturing and logistics to automated production environments. Its advanced control capabilities and reliable performance make it particularly well-suited for operations requiring precise automation and monitoring capabilities.

Manufacturing

In manufacturing settings, the T-King XAC-A8913 excels at controlling automated systems and machinery. It ensures precise control over production processes, enhancing efficiency and maintaining consistent quality standards across operations.

Logistics and Warehousing

The system optimizes warehouse operations through efficient management of automated equipment, including conveyor systems and robotic solutions. This automation significantly reduces manual labor requirements and improves operational accuracy.

Automated Production Lines

For automated production environments, the T-King XAC-A8913 provides comprehensive control over entire process chains. It monitors equipment status, adjusts operational parameters, and ensures seamless coordination between different production stages.

Read This Blog:https://sportnexgen.info/mednetwerk/

Frequently Asked Questions

What is the T-King XAC-A8913 used for?

The T-King XAC-A8913 finds extensive application across industrial settings, particularly in the manufacturing and construction sectors, where its precision engineering and reliability make it ideal for complex automated operations and heavy machinery applications.

How can I read the T-King XAC-A8913 diagram effectively?

Begin with the fundamental symbols and notations, progress to understanding the overall layout and component relationships, and consistently practice identifying different systems and their interconnections. Regular consultation of the diagram will enhance your comprehension and interpretation skills.

Where can I find a copy of the T-King XAC-A8913 diagram?

Official copies of the diagram are available through manufacturer documentation, technical service manuals, and authorized distributor networks. Always ensure you’re working with the most current version for accuracy.

What should I do if I need help understanding the diagram?

Seek guidance from experienced technicians, consult manufacturer support resources, or engage with technical training programs. Professional support services can provide detailed explanations and practical insights.

Can the T-King XAC-A8913 diagram be used for troubleshooting?

The diagram serves as a powerful troubleshooting tool, enabling technicians to trace system connections, identify potential fault points, and implement effective solutions by understanding the complete system architecture.

Conclusion

The T-King XAC-A8913 diagram represents far more than a simple technical schematic; it serves as a comprehensive guide to understanding and managing this sophisticated piece of industrial equipment. Its detailed documentation of system interactions, component relationships, and operational workflows makes it an indispensable tool for professionals in the field.

Beyond its immediate technical applications, mastery of the T-King XAC-A8913 diagram opens doors to enhanced operational efficiency, reduced downtime, and improved maintenance practices. This understanding contributes significantly to the overall effectiveness of industrial operations and the longevity of the equipment.

Hayyat is a talented content writer and digital marketer with expertise in SEO, social media management, and online marketing. She excels at creating impactful, data-driven content to help businesses connect with their target audience and achieve measurable outcomes.